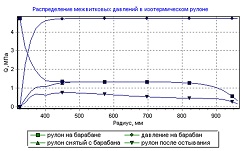

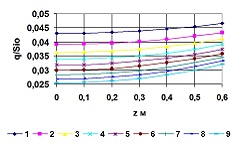

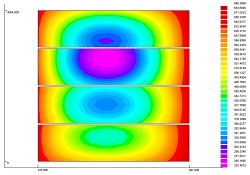

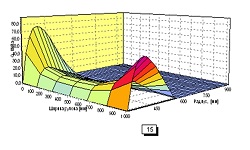

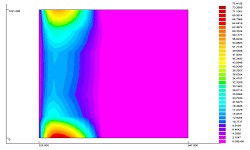

Defects on the strips surface (stickers, spots of adhesion, scratches and marks), as well as loss of stability of coil (slippage under its own weight or the formation of a defect "coil bore collapse") are associated with irrational stress-strain state of coils when they were wound.

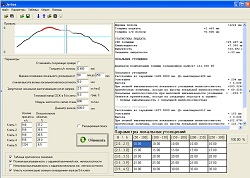

In this relation it is an important task of improving and developing new methods and computer system for calculating the SSS of coils, allowing:

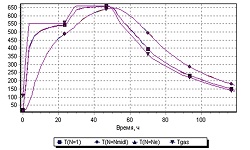

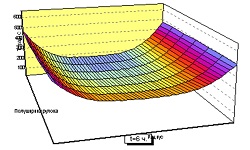

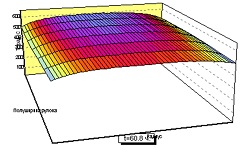

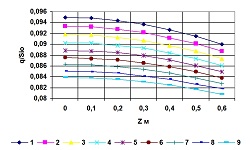

- predicting the SSS of coils during and after winding in cold rolling mill, as well as during coils annealing;

- determining the optimum conditions of winding and annealing in bell furnaces with minimal probability of turns welding during coils annealing or slippage of coils in the subsequent unwinding in the process of tempering.

The aim of the work is to develop new elements of the technology of strips cold rolling and winding in coils, taking into account the patterns of winding temperature changes, and ensuring the quality of the strips surface.

Period: 2003 - 2004

Customer: JSC NLMK

The aim of the work is to improve the technology of cold rolling, winding in coils, annealing, and strips tempering based on the data of temperature and flatness distribution by the length and width of strips, ensuring quality of the strips surface.

The main results:

- Increase by 1.5-2.0% of rolled strip output of I group of surface quiality;

- Increase productivity by 7% in mill 2030 during rolling strips of thicknesses 0.5 - 0.6 mm;

- Reduction by 25% rejection rate by defect of cold rolled strips "stickers".

Performed a complex of works to improve the strip surface state, served as a basis of innovative solutions to the problem described in в scientific papers and thesis.