Period: 2000-2001

Customer: OJSC "NLMK"

Period: 2000-2001

Customer: OJSC "NLMK"

Period: 2001-2002

Customer: OJSC "NLMK"

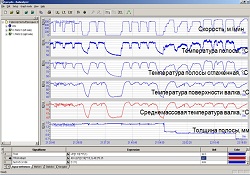

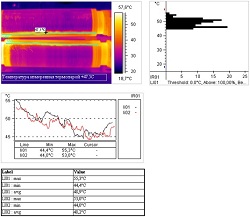

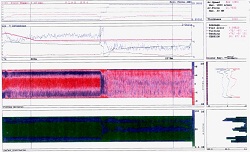

The aim of the complex research is the development and implementation of control methods and improvement of technological processes of cold rolled strips production, ensuring reduction in rejection by flatness and improving the efficiency of the equipment, control systems and technological modes of treatment.

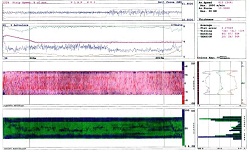

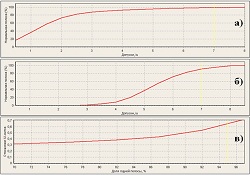

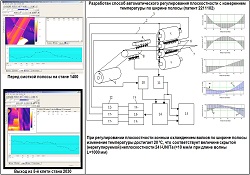

Experimental study of the effect of velocity and strain-force modes on the thermal conditions of rolling and the effectiveness of strips flatness regulation

CONFIRMED overall economic effect amounted to 67.726 million rubles.

Performed a set of works to improve the flatness of the strips, formed the basis of significant practical results presented in scientific papers and thesis.