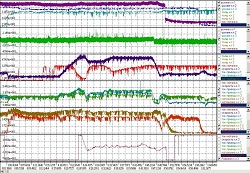

Scientific and technical audit – is a structured process, whose goal is a comprehensive, systematic study of technology and performance of the rolling mills. An audit includes examining of technology, equipment, automation systems and operational practices to determine their impact on the quality and performance. The results of the audit are:

- conformity assessment of technological modes of production to the best analogues;

- assessment of productivity, which determines whether the work of the mill or other aggregate corresponds to world level achieved in the given industry;

- diagnosis of the causes of specific manufacturing problems;

- recommendations and design solutions to address existing problems.

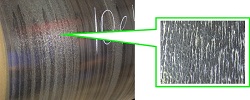

The aim of the audit is to identify shortcomings of the existing cooling system of work rolls in finishing stands, suggest possible options for increasing its effectiveness and determine the appropriate technical measures.

scientific and technical expertise of cold rolling mills, "Kvarto-400/1000h1200 SCODA», «Kvarto-250/750h900 (№ 11)", "Kvarto-150/500h450" and "Kvarto-375/1000h1000 (Tandem 1000)" AZOCM

Period: 2007

Customer: SSPE "Industrial Computer Systems"

The main customer: AZOCM

The aim of the audit is to make recommendations to modernize the equipment of rolling mills, equipment instrumentation and automation systems to improve quality of strips - namely, reducing the gage, flatness variation and improve the quality of the strips surface.