The developed system of vibration control of continuous cold rolling mill is used

for continuous monitoring of the dynamic situation in the continuous mill and rolling process control in

real time

in order to increase the operating speed and productivity of the mill.

General information about the system

Vibration control system is designed to control the vibrational situation in the cold rolling mill in

real time and aims

to prevent the entrance to the phase of a cascade its growth, accompanied by the mill roaring.

The system can automatically reduce the speed to the optimal value when the resonant vibration is

detected.

The system includes a diagnostic function of periodic defects in thickness during rolling.

- control of oscillations synchronization in the stands and mill control;

- horizontal stability control of work rolls chocks;

- control of reductions and tensions in the stands of continuous mill;

- control of high-frequency longitudinal strips gage variation;

- control of a neutral angle in the deformation zone;

- equipment diagnostics.

Mode of system operation is non-stop.

Software and hardware

VCS includes a personal computer equipped with a Windows based general purpose

software and specific (application)

software of our development. Special software is a set of software modules that provide collection and

processing

of data received from the mill process control system, as well as the realization of the objective

functions of the system.

The configuration of measuring devices includes: a set of accelerometers with magnet holders, ADC/DAC

converter,

cables and associated signal conditioners.

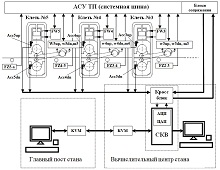

Block diagram of VCS

Three last stands of the mill are shown, the rest stands are similar.

Examples of VCS work

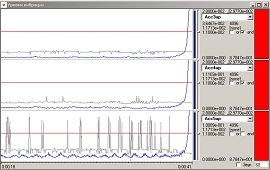

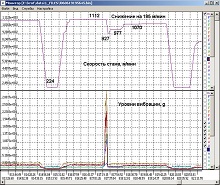

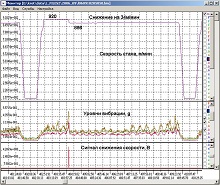

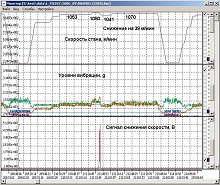

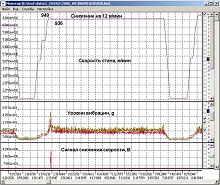

The drawings show examples of resonance vibration occurrence and response of the system.

The system working window "Levels of vibration"

An example of speed reducing by the alert produced by the system

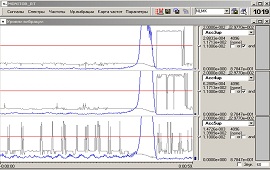

Analysis of the recorded vibrations data files of the mill and VCS work during rolling of a single strip

Example of VCS response (34 - 41 seconds) and speed reduction by the alert produced in system (for the demonstration of resonant vibration sensitivity of VCS was reduced).

The smaller values of speed reduction in automatic mode by VCS are due to start of slowing down at an earlier phase of the resonant vibration. This is achieved through instant electrical signal supply to reduce speed in automatic mode without the human factor - the reaction and attentiveness of the operator. The earlier impact on the mill speed, the lower value of speed reduction is necessary to normalize the dynamic situation in mill.

The main results of the VCS use

Studies were carried out within 3 months (July-September 2006) in the initial period after the date of

VCS commissioning.

The results were compared to the same extent in the base period (April-May 2006). Overall analysis of

VCS

operation on endless cold rolling mill 2030 NLMK (for the period

July-September 2006) in automatic mill speed control has shown:

- reliable (95% of cases), not later than 3 seconds, recognition of the resonant vibration ("roaring") of mill;

- automatic elimination of cases of "roaring" of the mill without the intervention of operators;

- minimum (10-15 m / min) decrease in the mill speed in case of dangerous vibrations;

- ability to recover previous speed (manually);

- reduction of the periodic strip defects associated with the resonant vibrations;

- increase due to that of the average mill operating speed, as each subsequent case of "roaring" of the mill takes place at a slower speed because of the deterioration of the rolls surface;

- reducing the probability of resonant vibrations of considerable amplitude reduces the number of possible strip breaks.

The volume of sample data for the period under review allows to state that the automatic mill speed control through the VCS has increased the speed of thin strips rolling:

- average values of rolling speed – by 11%;

- maximal achievable rolling speed – by 8%;

- values of speed drops reduction – by 31%.

Modules supplied with the system

- monitor_rt - vibration and technology parameters monitoring and mill speed control in real time;

- monitor_stat – batch statistical processing of vibration files;

- monitor_view – viewing and detailed analysis of the vibration records files.

Each module is designed for a specific group of users of the system and solving a certain set of tasks. A number of methods used in the VCS for equipment diagnosis and detection of vibration threatening situation are as KNOW-HOW. New versions of VCS (tested in manual mode) can include modules not only reducing, but also automatically increasing the mill speed, and also changing the settings of process parameters (reductions, tensions) for better management of the rolling mill and increasing productivity.