The automatic flatness control system of the strips is a knowledge-based control technology,

without

which today is unthinkable a competitive manufacturing of rolled products with high strip flatness.

General information about the system

The first domestic AFC based on non-contact flatness meter IP-4М

is implemented at the Novolipetsk Metallurgical Combine in the framework of technical upgrading program.

AFC, which uses non-contact methods for measuring the flatness and temperature

of strips,

is designed to automatically measure and control strips flatness on 1-stand and continuous cold rolling

mills and

the collection, storage, visualization and recording of process information.

- "Metaltehnomash" Ltd. and the Iron and Steel Institute of NAS of Ukraine — developed project and the overall system, including methods of calculating the parameters of the process, data collection, synthesis and optimization of control impacts through the rolls bending and tilting in temper mill (implemented in a software environment CodeGear RAD Studio), HMI interface programming (PC577 12 Key with software of Siemens company - Simatic WinCC flexible 2005 SP1), as well as system backup process parameters and their subsequent analysis (based on Microsoft SQL server databases);

- CJSC "Inkomet" — created the flatness meter IP-4М with its installation project, including a software package DAC32WIP4, processing data from the television and thermal imaging cameras;

- OJSC "Chermetavtomatika" — developed technical and implementation project, including the composition of the equipment and its deployment, upgrades to the scheme of existing equipment, connecting signals from the existing ACS кto the controller Simatic S7 300, which is used in the AFC. Organization of data exchange between the controller Simatic S7 300 and OPC server;

- OJSC "NLMK" - provided overall coordination and project funding.

- measurement and control of hydraulic bending and rolling forces separately from the drive and service side (tilt);

- visualization of the desired and actual cross-section diagrams of strips on the operator monitor;

- input and ongoing changes specified by the operator of target flatness diagram of strips from the control station;

- collect data on the strips flatness and technological information;

- storing the collected information for at least 1 year;

- visualization parameters of flatness in the form of trends and numerical values, taking into account the taken dimensions;

- review of existing information on the AFC work in the form of graphs and tables linked to the production unit (lot number, roll number);

- print the accumulated data in the form of reports, graphs and tables (lot number, roll number), (a form of reporting is coordinated at the stage of detailed design by the customer and the developer);

- statistical processing of technological information (defined min, max, mean and other parameters);

- implementation of the transfer of integral strips flatness characteristics with reference to the lot number, roll number by the customer agreed exchange protocol.

Software and hardware

Software includes system software based on Windows, and also a complex of system, application, and

special programs

that implement the system functions. The special software consists of a control program and four

subsystems providing

its work. The special software consists of a control program and four subsystems providing

its work.

1st subsystem - measurement of flatness and temperature with IP-4М.

The measurement results are transmitted through the DIM server in the control

program for processing.

2nd subsystem - system of controller management. This system provides a link of AFC

to the current ACS.

3rd subsystem - a system of visualization. Allows the operator to control the strips

parameters and process parameters of tempering.

4th subsystem - a backup system. This system provides storage of all process parameters

used in the AFC.

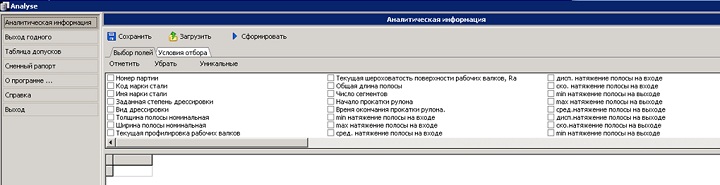

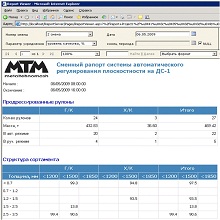

Also, AFC uses client-side applications AnalyseClient, FlatResult and

Web-report –

shift report. Client applications are installed on the remote PC in the

enterprise network and are

used to analyze the results, as well as process parameters of tempering.

The composition of the measurement devices include: workstation, server, database, operator panel (based

on Windows),

the controller Siemens S7-300, flatness and temperature meter IP-4М

(workstation, a video camera, thermal camera), cabinets, cables, etc.

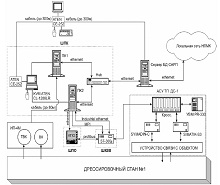

Block diagram of the AFC hardware

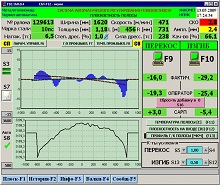

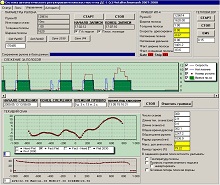

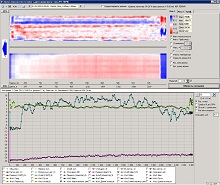

Examples of AFC work

The output side of the temper mill with an installed electronic-optical system IP-4М for measuring the strip flatness and temperature

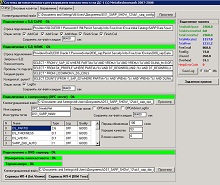

Example of interface windows of subsystem and client applications within the AFC control program

The main results of AFC use

Studies were carried out within 2 months (April-May 2009) during the period of AFC guarantee tests.

Based on the results of data processing about the AFC performance in April-May

2009,

definitely revealed its positive effect on the flatness of the products. At various times and at

different ranges

of tempered strips, flatness improvement, expressed as a mean value of the amplitude of flatness

variation (wave height),

was between 10..30%. The systematic positive impact of the system led to a decrease in rejection by the

finished

product flatness.

In late May the system was commissioned by customer.