Studies of resonant vibrations (chatter) and the development of vibration control systems of cold rolling and temper mills are carried out in several directions:

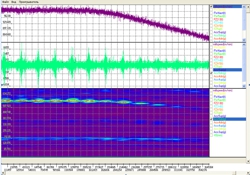

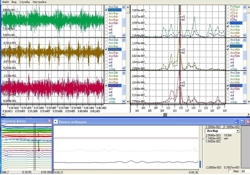

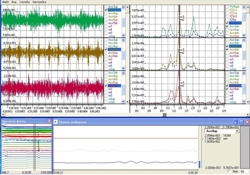

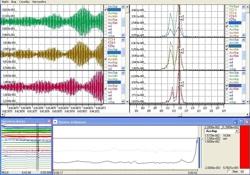

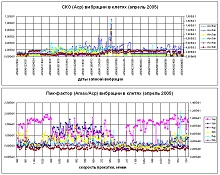

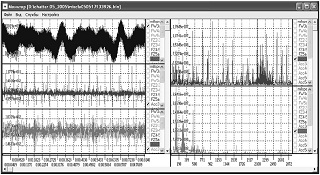

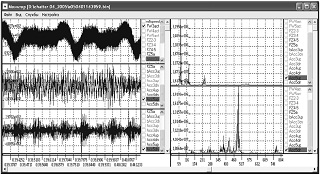

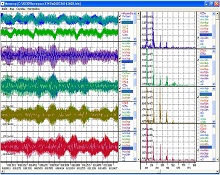

- installation of stationary systems for vibration monitoring;

- development of methods and devices for passive and active damping of vibrations;

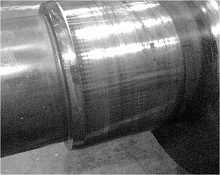

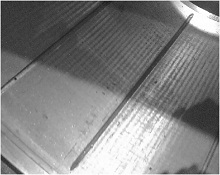

- development of methods for contactless control of chatter marks on rolls and strips;

- optimization of process parameters and machines design of rolls grinding;

- development of methods of mill speed and technological parameters control of the rolling process;

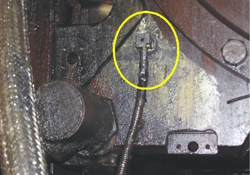

- development of diagnostics methods of equipment in stands and drive lines of the mill;

- analysis of the influence on vibration of coolant parameters and quality of hot-rolled strips.

The aim of the work is to improve the technological modes of strips rolling, to increase average rolling speed and hourly performance through the use of vibration monitoring system.

Period: 2005 - 2006

Customer: OJSC "NLMK"

The aim of the work is to reduce resonant vibrations at the mill 2030 through the development of new technical solutions with the use of vibration monitoring system and equipment diagnostics.

The aim of the work is reducing resonant vibrations at the mill 2030 through the development of new technical solutions with and equipment diagnostics.

The main results of performed works:

- Developed and commissioned into permanent industrial operation a vibration control system and speed control of the cold rolling mill 2030, has raised by 10% the average speed of cold rolling of thin strips with thickness less than 0.8 mm.

- Developed and implemented in VCS the patents 2212289 and 2338609 of the RF.

- The estimated economic effect of the VCS implementation (for the conditions of mill 2030) is 240 thousand Euros per month (2007).