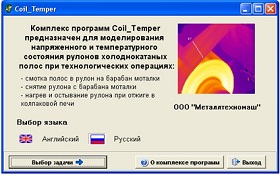

Software title

CoilTemper3D - program for calculating the thermal and the stress-strain state in the process of coils

rolling-winding and to predict the conditions (intensity) of turns adhesion in the process of heat treatment

of coils in bell-type furnaces.

The functional purpose

CoilTemper3D program is designed to calculate time dependent heat (thermal) and the stress-strain state of

cold

rolled strips taking into account the initial non-isothermal conditions of coiling, flatness and surface

roughness

of the strips, as well as modes of coils heating and cooling in bell-type furnaces for a given heat transfer

coefficient and the cyclograms of the protective gas temperature.

The main functional advantages

- Methods are implemented for calculating three-dimensional stress-strain state of strip coils in the process of heating and cooling with accounting the initial thermal state of the coil, the variation of the rough strips coiling tension. It is taken into account the mutual influence of the interturn pressures and thermal resistance;

- on the basis of the developed model algorithms are implemented for calculating non-stationary thermal and the stress-strain state of cold rolled strips coils in the process of winding on a reel drum, removal from the reel drum, heating and cooling of coils for a given heat transfer coefficient and temperature functions of protective gas simulating the conditions of heat exchange of coil with a high-protective atmosphere in bell-type furnace. The algorithm takes into account non-ideal thermal and mechanical contact on the adjacent surfaces of strip turns;

- particularities in the formulation of the problem are caused by the state of the contacting surfaces of the layers – variations of flatness and surface roughness. These features are accounted by the use of generalized parameter of non-ideal contact, which allows in terms of compatibility of deformations in a coil to take into account the convergence of the contacting surfaces as a function of interturn pressures;

- in the method of calculation of TSSS, it was taken into account the effect of additional thermal stresses generated during cooling and heating of coil, when a variable temperature field appears there.

The computer system is part of the methodology of solving scientific and practical problems of improving the quality of the surface of cold rolled strips in coil method of production.

CoilTemper3D may serve as a means of optimization of technological modes of rolling, coiling, and recrystallization annealing of cold rolled strips in bell-type furnaces, minimizing the probability of occurrence of surface defects of strips such as "bending lines" (so-called "fraction"), marks of turns slipping (scratches), as well as to monitor the stability of coils sinking under their own weight or the occurrence of defects of winding coils such as "bird" (when the internal turns of a coil, losing stability, violate a round shape, making it impossible the further processing of the coil).

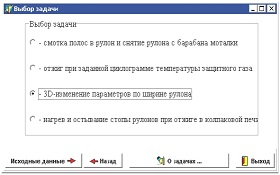

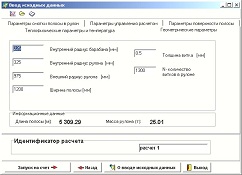

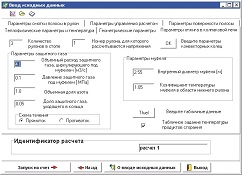

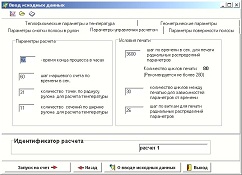

Examples of dialog "Enter the initial data"

Note:

Depending on the selected task, dialog boxes may have

different input parameters

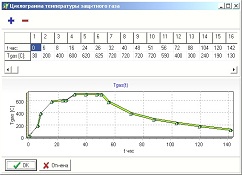

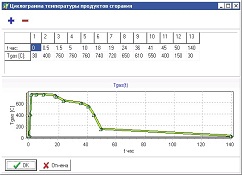

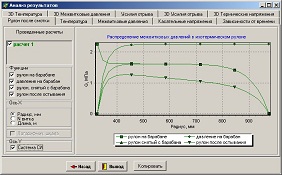

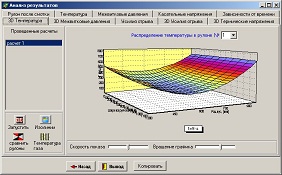

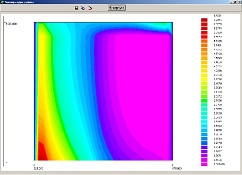

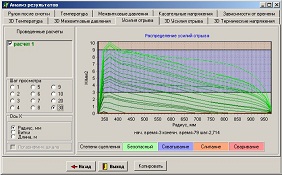

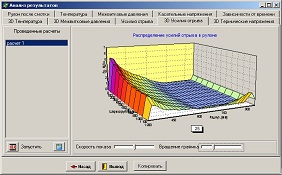

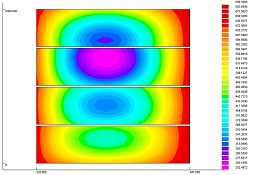

Examples of dialog boxes, "Analysis of the

results"

Note:

Depending on the selected task dialogs can have

different types of calculation result output