Software title

HRSProfileControl - program for calculating the cross-section, the flatness of strips and control

impacts during hot rolling.

The functional purpose

HRSProfileControl provides calculation of the components (the wear and elastic deformation, thermal

expansion, the

profile of rolls) of the strips cross-section in hot rolling in the finishing group of stands WS HRM,

and reversible one- or two-stands Steckel mill with coilers in furnaces.

The program is designed to assess the effectiveness of various control algorithms for transverse profile and

flatness

of the strips in the mills, equipped with complex of control tools, such as changing the relative

orientation of the

rolls (parallel, crossing the axial shifting), forced bending (+/-) and thermal profiling (change of the

total flow

rate and / or by zones). It is possible to simulate the use of tools in various combinations.

Depending on the chosen set of tools and programs rolling program allows you to select the optimal

parameters work

and backup rolls profiles, as well as the range of control action.

The main functional advantages

- for a given program of rolling at any stage of the rolls campaign it is calculated their worn-out, the thermal profile of the active surface line, as well as elastic deformations of roll unit. By comparing the calculated and given the cross-sectional profiles of the strip, taking into account rolls profiles the form and parameters of control impacts are determined by the following channels:

- parallelism of the rollers;

- crossing of the work rolls relative to each other and crossing backup rolls relative to work rolls to compensate the axial loads encountered in the work rolls;

- axial shift of work rolls;

- additional bending and counter-bending of work rolls;

- sectional cooling of the work rolls.

- wear of rolls is calculated based on the use of different techniques of their axial shift schedule:

- cyclic shift of rolls CS;

- universal profile control URP with "cigar-shaped" work rolls or rolls with a one-sided slant on the edge of the barrel;

- continuous change in the rolls profile CVC with a convex-concave rolls.

- during control of transverse strip profile with different thickness and width the critical values of deformation, resulting in flatness are taken into account.

Algorithms implemented in HRSProfileControl, designed for use in automatic control systems transverse profile pages to WS HRM.

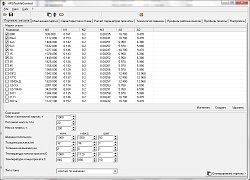

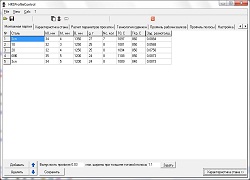

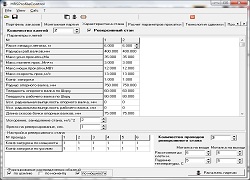

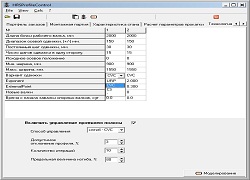

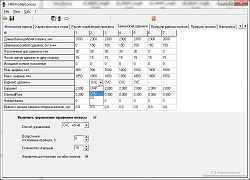

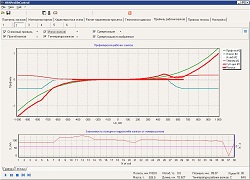

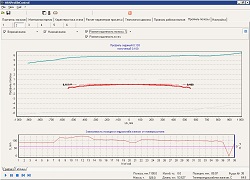

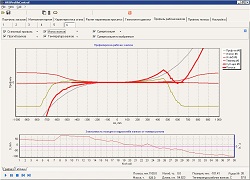

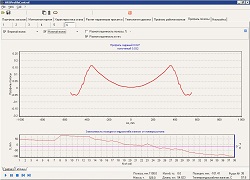

Examples of dialog boxes of HRSProfileControl program

MODELING OF ROLLING AND CONTROL ROLLS AXIAL SHIFTING

(two-stands Steckel mill)