"Metaltehnomash" Ltd. was founded on the basis of the Thin Sheet Production Department of Iron and Steel Institute NAS of Ukraine in 1993 by the initiative of Prof. V.L. Mazur and Prof. A.M. Safyan during difficult times after the USSR disintegration. At this time, commercialization of scientific and technological developments had not yet gained of widely development. Metallurgical enterprises have sharply reduced the amounts or even stopped funding of scientific research. However, solutions remained in demand on technologies improving, industrial automatic control systems, which could be implemented in the shortest terms and with relatively small investments.

To survive in a difficult time for the country, it was necessary to seek new approaches and methods of services provision. Annual RDW or RDEDW and implementation projects with quarterly reports signing and payments has not found financial support in post-Soviet era in the metallurgical and machine building enterprises, which experienced an acute shortage of financial resources. But barter was possible. That is, payment for provided services by the companies’ products. To make a profit, it was necessary to organize not only the research and implementation of technological developments, but also address issues of commercial nature, related to the sale of products obtained during scientific research. At that time it was the only way to survive.

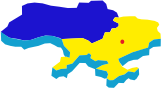

After stabilizing of economic situation in CIS countries, Metaltehnomash comes into foreign activity. In the metallurgical enterprises, the situations more frequently occurred, which required immediate solutions of problems related to product quality. Hence, it was necessary to solve these problems not only within the framework of the annual RDW projects, but within tight deadlines.

In 1999, NLMK assigned to Metaltehnomash the solution of task of strip flatness improvement and the scientific and technical assistance on recently purchased an automatic control system of strips flatness in tandem cold rolling mill 2030. Metaltehnomash brilliantly copes with the task, and as a result NLMK implemented and patented several new elements of the strips cold rolling technology in tandem mills. NLMK developed new products. The economic effect is 68 million rubles and made the investment payback period less than one week.

By the first success results the contracts are signed further on a regular basis and the development of mutually beneficial cooperation of the MTM and NLMK continued.

In 2006, it was commissioned for permanent industrial operation a system for vibration and speed control of the 5-stands cold rolling mill 2030 NLMK. As a result, the average rolling speed on the mill has been increased by about 10%. It is not difficult to assess the economic efficiency of such system with possible annual production of the mill up to 2.5 million tons of cold rolled strips.

In 2009, it was commissioned for permanent industrial operation on temper mill 2030 (TM-1) the innovative firstly created in the CIS countries system of automatic control of flatness of strips with the use of contactless methods to measure their flatness and temperature. The average improvement in the flatness of strips is 20%.

In 2009-2010, system is developed for calculation, optimization and work rolls cooling control in finishing stands WS HRM. As a result, temperature is reduced and stabilized over the barrel; wear decreasing and prolonged lifetime will be achieved of the work rolls as the most expensive replaceable components of rolling mills.